Oil and Water Separators

Air Technologies® offers oil and water separators for every brand and model

OSC 35-2400 Oil and Water Separators

- Inlet capacity: 35 to 2360 l/s, 75 to 5003 cfm

- Filtration: oleophilic and activated carbon filters

- Oil content: less than 15 mg/l

OSC – Advanced technology for all compressed air condensates

The new and extensive OSC range from Atlas Copco uses patented technology to separate all kinds of compressed air condensate.

The multi-stage separation process, using both buoyant oleophilic filters and activated carbon, ensures exceptional performance, long and proven filter lifetime and trouble-free operation.

All oil / water separators are manufactured in accordance with Atlas Copco’s Quality and Environment Management System. These systems comply fully with ISO 9001 and ISO 14001. All Atlas Copco separators are tested to perform under the most demanding conditions.

Atlas Copco OSD

Condensate from oil-injected compressors contains oil in considerably higher quantities than legislation allows to be drained into the environment.

Atlas Copco’s OSD compact oil-water separator cleanses the condensate to a quality far superior to any legal requirement.

The GA 11 to 315 kW oil-injected screw compressors can be equipped with an integrated OSD which delivers a residual oil content of less than 10 mg per liter of condensate.

- Suitable for oil-injected compressors up to 90 kW

- Multiple installations for higher capacities

- Fully automatic separation

- No use of active carbon

- Oil residue, re-usable under controlled conditions

- Long filter life

- Effluent purity independent of filter condition

- As good as maintenance-free

- Extremely reliable

Atlas Copco OSM

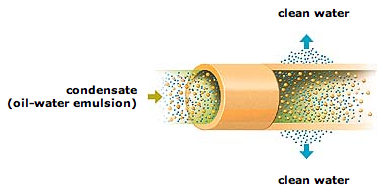

It is globally recognized that condensate from oil-injected compressors is an oil-water emulsion, classified as oil residue, and must not be drained into the sewage system nor into the environment. Legislation, worldwide, has become more and more stringent as to the disposal of this oily waste water.

With the introduction of the OSM 500 and 900 oil-water separators, with the latest filter membrane technology, Atlas Copco offers a most cost effective, safe, environmentally friendly and simple system to handle condensate from oil-injected compressors, fully in compliance with governmental regulations.

Effluent purity meets most restrictive current and future legislation

- Guaranteed effluent purity less than 5 mg oil/l

Lower disposal cost

- Waste minimization

Safe operation and lower investment

- No possibility of high oil content in effluent

- Filtration of stable emulsion without the need for adding chemicals

Low maintenance, low operating cost, easy to install

- No active carbon filter nor other chemicals needed

- Simple and reliable system

Latest filter membrane technology

The membrane separates the smaller molecules such as clean water from the larger molecules such as oil.